PowerStab™ 622 is a polymeric hindered amine light stabilizer (HALS) designed for long-term UV protection in plastics and coatings. Its high molecular weight polymeric structure ensures superior performance in demanding applications. It is non-discoloring, low volatility, and offers excellent resistance to migration, with low basicity for reduced interactions with pigments and other stabilizers. PowerStab™ 622 is widely used in polyolefins, polyurethanes, and elastomers, and is approved for food contact applications in many regions.

| Synonyms | Tinuvin 622 SF, Uvinul 5062H, Omnistab LS783, Songlight 6220, SABO_Stab 62, Lowilite 62, Eversorb 94, Chiguard 622LD, EVERSTAB LS 622, Chisorb 622LD. |

CAS Number | 65447-77-0 |

EINECS Number | 613-797-0 |

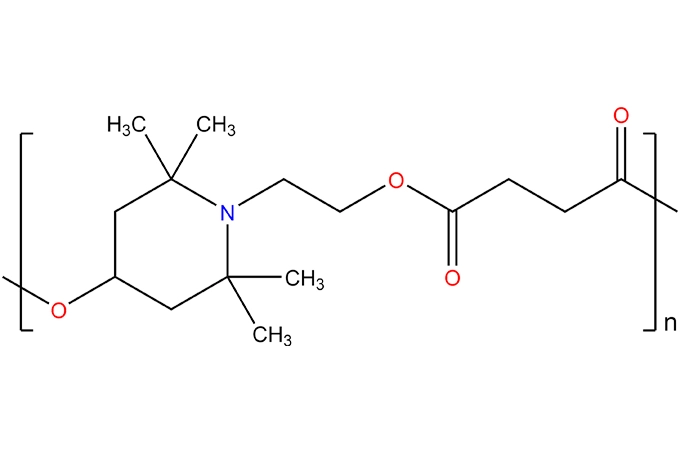

Chemical Structure |

|

Chemical Formula | (C15H25NO4) n |

Molecular Weight | 3100-4000 |

Packing | PowerStab™622 is supplied in 25kg net/carton. |

Note | All information in the leaflet is based on our present knowledge and experience. We reserve the right to make any changes according to technological progress or further developments. Performance of the product described herein should be verified by testing. We specifically disclaim any other express or implied warranty of fitness for a particular purpose or merchantability. We disclaim liability for any incidental or consequential damages. |

Excellent UV stabilization for long-term protection

Non-discoloring performance

Low volatility and excellent resistance to migration

Low basicity - minimizes interaction with pigments and other additives

Maintains product appearance without yellowing

Suitable for food-contact applications (EU, USA, etc.)

Synergistic with UV absorbers and other HALS

Long-lasting, polymer-bound stabilization effect

Appearance | White to yellow granular powder |

Melting Point (°C) | 50-70 |

Specific Gravity (20°C) | 1.22 |

Volatiles (%) | Max.0.5 |

Color of solution 425nm (%) | Min.98 |

Color of solution 500nm (%) | Min.99 |

Melting Point (°C) | 50-70 |

Ash (%) | Max.0.1 |

Solubility [20°C] | % w/w |

Acetone | 4 |

Chloroform | >40 |

Ethanol | 0.08 |

Ethyl acetate | 3 |

n-Hexane | <0.01 |

Methanol | 0.05 |

Methylene Chloride | >40 |

Toluene | 15 |

Water | <0.01 |

PowerStab™ 622 is recommended for use in polyethylene (PE), polypropylene (PP), EVA, polyurethane (PU), polyacetals, polyamides, elastomers, adhesives, and sealants. It is particularly effective in films, fibers, injection-molded parts, and pigmented or carbon black-filled systems.

Typical dosage levels range from 0.05% to 1.5%, depending on the polymer type and processing conditions.

In accordance with good industrial practice, handle with care and avoid unnecessary personal contact. Avoid continuous or repetitive breathing of dust. Use only with adequate ventilation. Protect skin. Avoid dust formation and ignition sources.

This product may be stored up to one year in a sealed container. Containers should be stored in a cool, dry area. Extended storage at elevated temperatures or exposure to direct heat or sunlight could reduce product life. Keep containers sealed when not in use.

For more detailed information please refer to the material safety data sheet.

PowerStab™622 is supplied in 25kg net/carton.

All information in the leaflet is based on our present knowledge and experience. We reserve the right to make any changes according to technological progress or further developments. Performance of the product described herein should be verified by testing.

We specifically disclaim any other express or implied warranty of fitness for a particular purpose or merchantability.

We disclaim liability for any incidental or consequential damages.