TINTOLL believes that implementing thorough Quality Control (QC) is important to ensure product safety and continuously improve quality so that our customers can use products safely and confidently, preserving their profits while maintaining process performance. We leverage existing expertise and assets to generate economies of scale and improve the resulting cost-effectiveness, efficiency and yield.

As one of the professional integrated specialty chemical companies providing a wide range of products and services to customers in various industries, all our production facilities are equipped with the latest systems and run on state-of-the-art equipment that is continuously upgraded. TINTOLL has the responsibility to prevent quality and product liability issues, while striving to further improve customer satisfaction by providing safe and reliable products and services. We strive to fulfill this responsibility in accordance with the following basic principles.

As a customer and market driven company, we provide technical and regulatory advice and support to our customers, enabling them to deliver high performance and compliant materials to their customers. We listen carefully to every customer's request and respond quickly and sincerely. Building on our Responsible Care activities, we strive for continuous quality improvement.

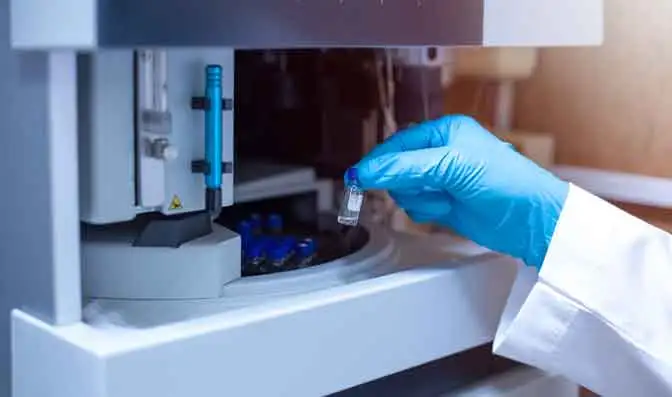

TINTOLL's quality management system is very sound (based on ISO 9001, ISO14001, etc.), and it is in the leading position in the industry. Our factories are staffed by experienced quality control teams who operate independently of factory operations to ensure that our customers' needs and expectations are met. This group is responsible for testing and verifying that incoming raw materials meet purchase specifications, ensuring that all in-process testing meets specified product, and ensuring that final product meets agreed customer specifications.

Each facility is equipped with sufficient analytical equipment to perform the required tests. Typical analytical equipment used by Sinopcc Group are:

• GC

• HPLC Automatic Titrator

• FTIR Fourier Transform Infrared Spectroscopy

• NMR

• Mass Spectrometry

• Particle Size Testing and Polarimeter for Chiral Testing

Additional equipment may be used or outsourced to audited and monitored third parties as required. Our analytical equipment is calibrated at a set frequency to ensure that our analyzes are complete and accurate.

In addition, we hold regular quality assurance meetings, share and effectively utilize quality information within the group, and continuously strive to improve quality. At the same time, we pay attention to quality assurance training, and are committed to improving quality awareness and transforming it into practice. In addition, we have a policy on conflict minerals that may raise human rights concerns and work hard to ensure that our customers' requests are met.

Product-related complaint information is organized into a quality complaint database for efficient use. The business area plays the main role in quickly responding to customer needs, and strives to improve customer satisfaction. Major complaints are aggregated company-wide and analyzed to prevent recurrence.